Context :

The normative requirements added to the extension of the warranty periods oblige the manufacturers of photovoltaic modules to set the bar very high in terms of quality in order to achieve and maintain the performance of their products over time, and this at all stages of the manufacturing.

Our discussions with many of you, equipment manufacturers and PV manufacturers about the first important step in assembling a module, namely the interconnection of the cells by soldering or gluing, have enabled us to realize how delicate this step in the process is.

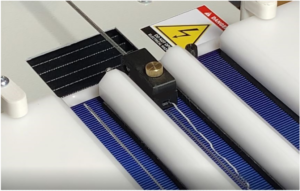

Indeed, we are talking about processes with high resistance such as gluing or welding on materials and components very thin and fragile. (tined copper ribbons or wires / very thin silicon wafers).

Observation :

In this context, the qualification of the interconnections of the cells with the conductors consists of a « destructive » test.

Although the current standards indicate possible peels at different angles, experts in the sector practice a 180° peel. The latter makes it possible in particular to reduce the risk of wafer breakage during the test, and also offers a better feeling when the operation is done by hand (which is still often the case for carrying out a few « touch evaluations » before perform instrumented measurements.

There are very good machines on the market for carrying out peeling operations and measurements. The latter are mostly designed for multiple industrial or laboratory uses, but often prove inadequate for the specific needs of the solar photovoltaic industry. Their price is high in view of a reduced use compared to their potential. Their use is ultimately tricky for the PV business.

PROPOSED SOLUTION

The positioning of our equipment is very clear : a SUITABLE work-tool for delicate peeling operations such as in the PV industry for example, SIMPLE and LEAN.

- SUITABLE

Field-specific features and accessories (holding torque, tray size & stroke, speed range, cell socket, wire tie,…)

- SIMPLE

Few components, mostly standard and from the most reputable suppliers. User friendly interface needing no training

- LEAN

Efficient, small, light, portable, affordable (do more with less)

To discover PEEL-LEAN© more in details, ask for our product data sheet and introductory video by clicking here.